Single Layer (Positive type):NPR9730T

Features

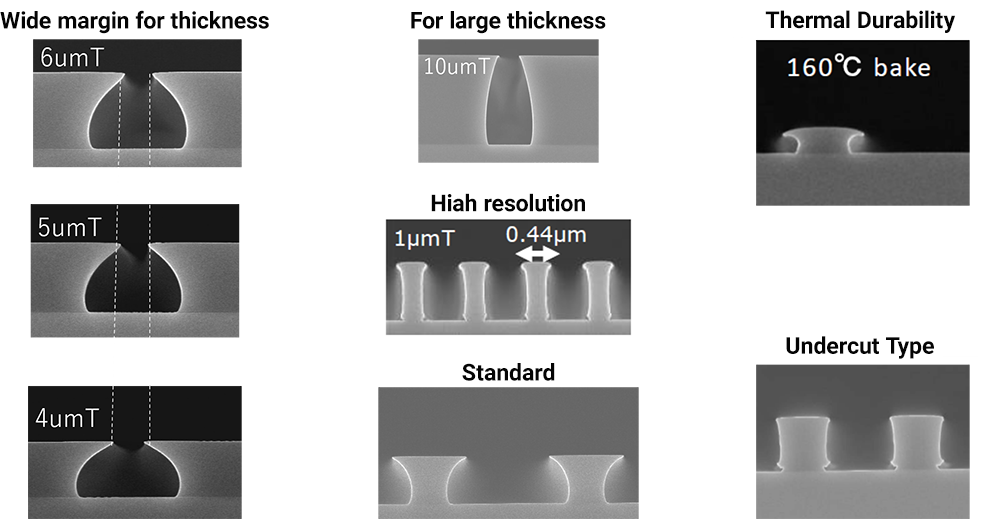

Positive resist for lift-off process.

Exposure wavelength range: g-line to i-line (broadband compatible).

Easy formation of anti tapered shapes without special processes

Good peelability.

Film thickness, line width, shape, etc. can be proposed according to the customer's requirements.

| Process | Conditions |

|---|---|

| substrate | 5-inch Si Wafer |

| pre-treatment | HMDS |

| Coating method | Spin coating |

| Prebake | 90℃, 120s, Hot plate |

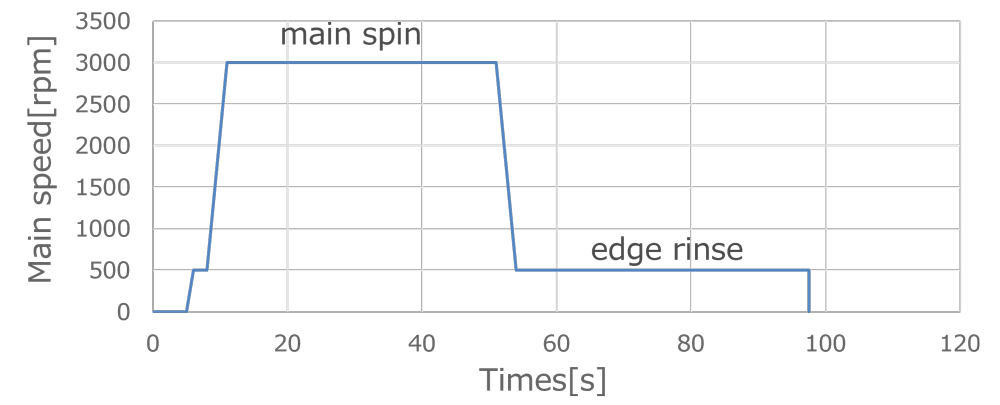

Coating Sequense

Example.) NPR-9730T 60mPa・s

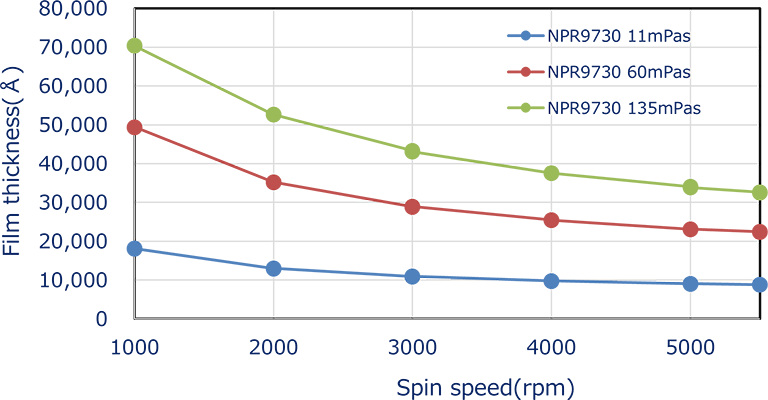

Spin curve

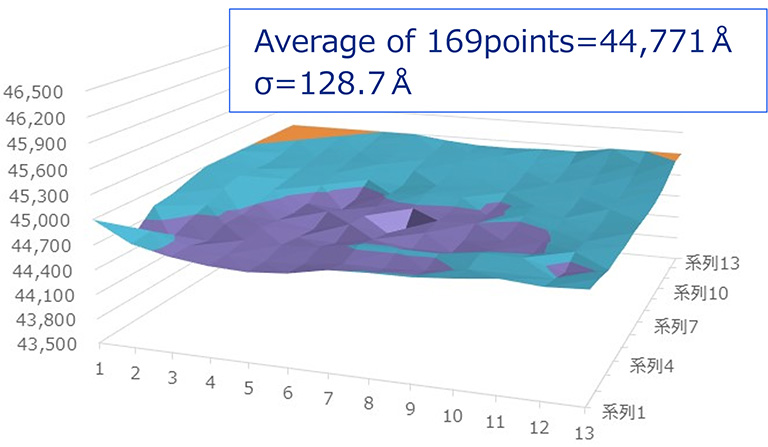

Film Thickness Uniformity

Product; NPR9730T(60mPa・s)

Process condition

Substrate; 5inch Si wafer

Spin speed; 1,020rpm

Pre-bake; 90℃, 120s, hotplate

Measurement condition of film thickness

13 columns x 13 lines = 169 points

pitch of each point = 5mm

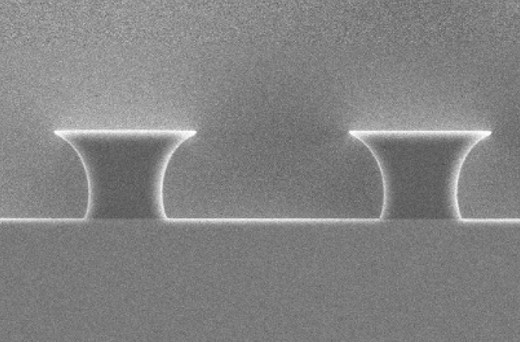

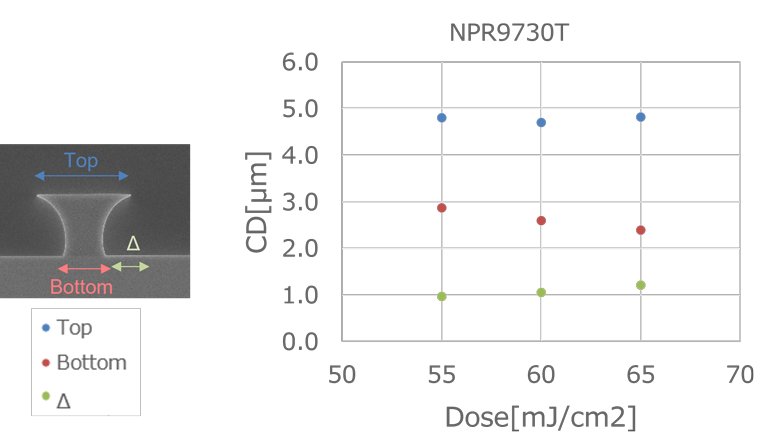

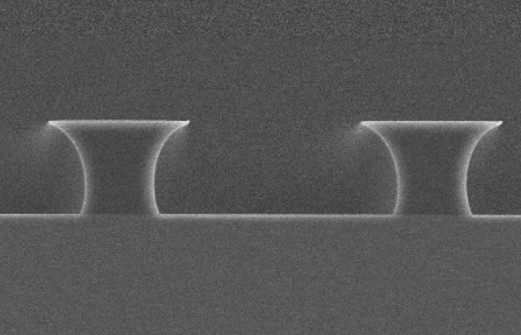

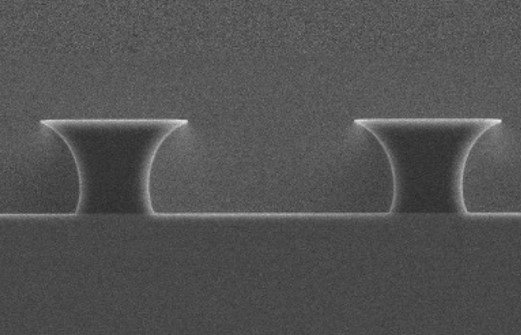

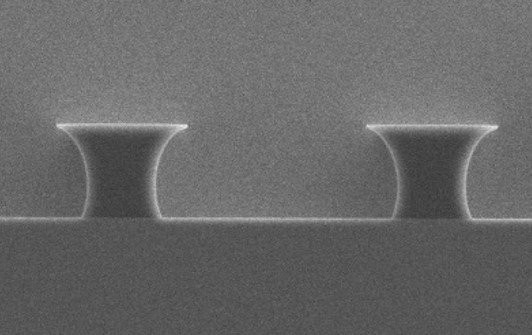

Exposure margin

| Dose | 55mJ/cm2 | 60mJ/cm2 | 65mJ/cm2 |

|---|---|---|---|

| NPR9730T |  |

|

|

【Process conditions】

- Substrate

- 5-inchs Bare-Si

- Coating

- Spin coat

- Prebake

- 90℃, 120s, Hot plate

- Thickness

- 3μm

- Exposure

- NSR-TFHi12, i-line stepper, NA=0.45, σ=0.6

- PEB

- Not applied

- Development

- 2.38% TMAH, 23℃, 60s, Single Puddle

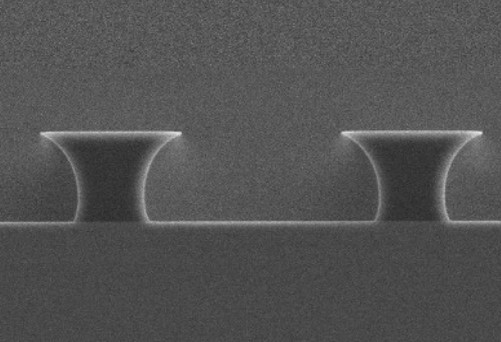

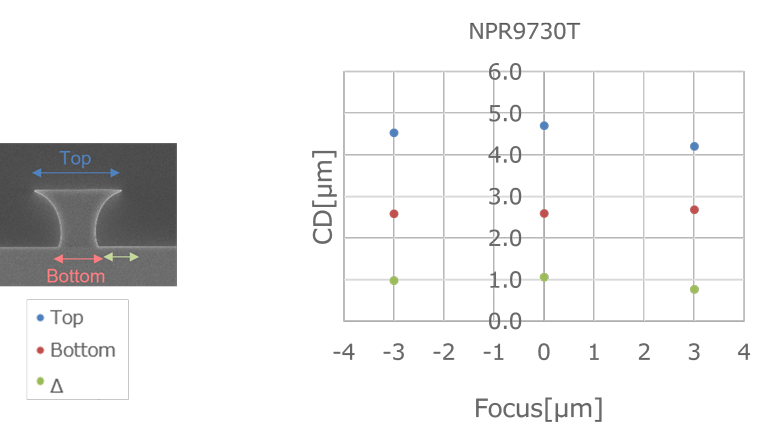

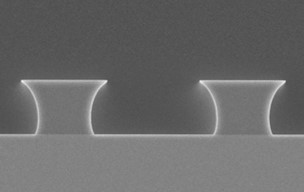

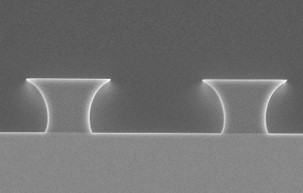

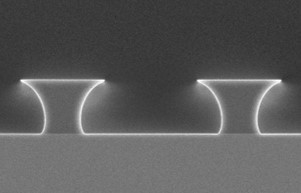

Focus margin

| Focus | -3μm | 0μm | 3μm |

|---|---|---|---|

| NPR9730T |  |

|

|

【Process conditions】

- Substrate

- 5-inchs Bare-Si

- Coating

- Spin coat

- Prebake

- 90℃, 120s, Hot plate

- Thickness

- 3μm

- Exposure

- NSR-TFHi12, i-line stepper, NA=0.45, σ=0.6

- PEB

- Not applied

- Development

- 2.38% TMAH, 23℃, 60s, Single Puddle

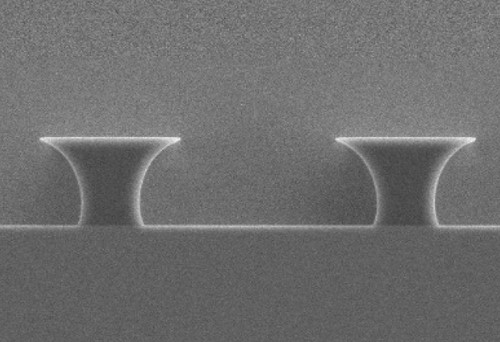

Development margin

| Development time | 55s | 60s | 65s |

|---|---|---|---|

| NPR9730T |  |

|

|

【Process conditions】

- Substrate

- 5-inchs Bare-Si

- Coating

- Spin coat

- Prebake

- 90℃, 120s, Hot plate

- Thickness

- 3μm

- Exposure

- NSR-TFHi12, i-line stepper, NA=0.45, σ=0.6

- PEB

- Not applied

- Development

- 2.38% TMAH, 23℃, 55, 60, 65s, Single Puddle

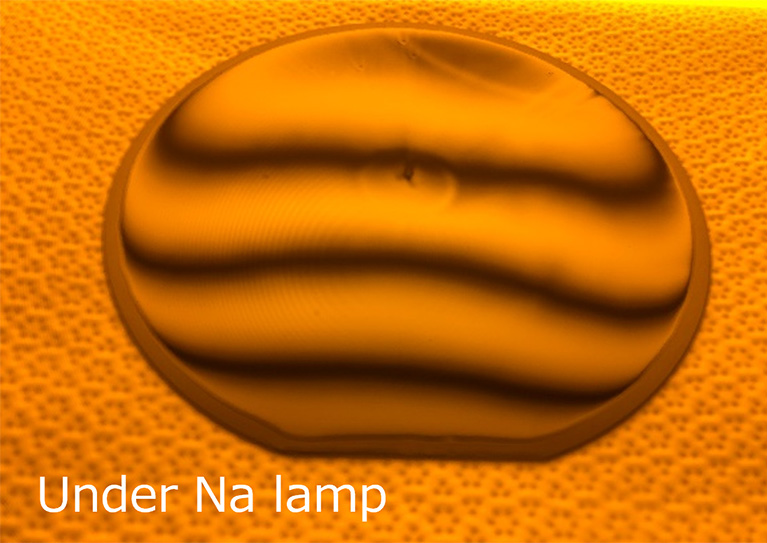

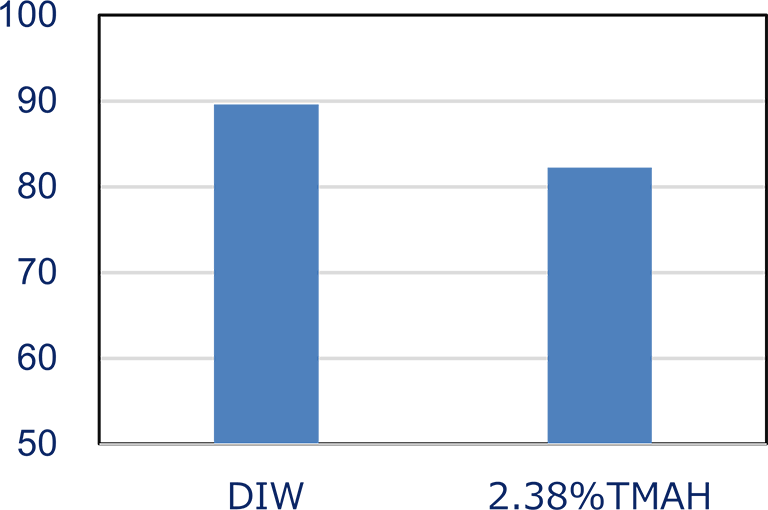

Contact angle of DIW and developer on PR film

Process condition

Substrate; 5inch Si wafer

Spin speed; 1,020rpm

Pre-bake; 90℃, 120s, hotplate

Measurement of contact angle

Dropping liquid on PR film; DIW, 2.38% TMAH

Waiting time from dropping to measurement of contact angle; 60s

| Product | Contact angle(°) | |

|---|---|---|

| DIW | 2.38%TMAH | |

| NPR9730T | 89.6 | 82.2 |

Photosensitivity and Dark erosion

Process condition

Substrate; 5inch Si wafer

Spin speed; 1,020rpm

Pre-bake; 90℃, 120s, hotplate

| Product | Film thickness(Å) | Dark erosion (Å) |

Eth (mJ/cm2) |

|

|---|---|---|---|---|

| after pre-bake |

after development |

|||

| NPR9730T | 50125 | 50644 | +519*1 | 56.5 |

*1 The dehydration bake wasn’t applied to PR film after development process.